Finite element analysis, dynamic simulation technology

Through advanced finite element analysis, kinematics and dynamics simulation analysis and calculation, based on accurate data support, it ensures that the structure of the vehicle is reasonable, the performance is excellent, and the reliability and stability of the entire vehicle are excellent.

Container loading trailer patented technology

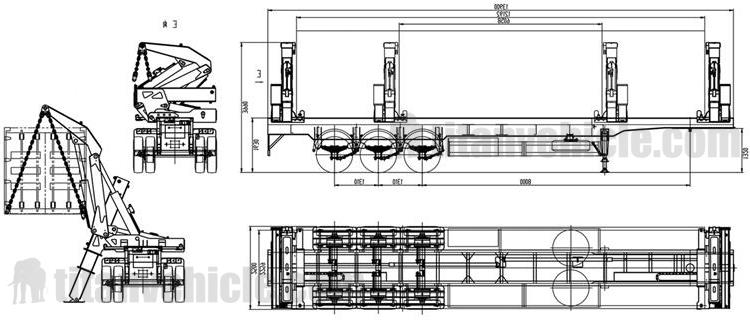

Integrating lifting, loading and unloading, and transportation, container loading trailer can make the self-loading and unloading of containers or other goods faster and more convenient;

Through the independent sliding of the middle hanger, with the front and rear hangers, it can load and unload empty or full containers of 20 or 40 feet or other specifications, or self-loading and unloading of other goods. It has a wide range of uses and high equipment utilization;

Through the action of the hanger, the loading and unloading and stacking operations of 1 row and 2 layers of containers can be implemented, which greatly improves the operational efficiency and the use of the equipment; Through the advanced operation and control system, only one person is required to operate, and it can be operated at a short distance or remotely, with convenient operation and high loading and unloading efficiency.

Intelligent safety protection system

Equipped with an inclination sensor to detect the status of 37 ton container loading trailer in real-time. When the vehicle is inclined, it can automatically alarm and intelligently lock related dangerous operations to ensure the safe operation of the container loading trailer.

Synchronous movement technology of boom

Using closed-loop control technology, flow control combined with angle feedback, the boom movement is adjusted by adjusting the hydraulic flow of the boom cylinder, so that the lifting points of each boom are synchronized when moving, and the container is synchronized before and after loading and unloading, which is convenient for container aligning operations.

Advanced electric proportional control technology

The device is controlled by a pressure-compensated electric proportional valve to realize the stepless speed regulation function to ensure smooth operation of the whole machine, good micro-motion performance and precise control.

Remote wireless control technology

The 20/40 Ft container loading trailer is equipped with Sany's self-made wireless remote control, which can realize the remote wireless control of the outriggers and hangers within 30m. The operation is convenient and fast, and the safety of the staff is effectively guaranteed.

Equipped with a wireless throttle potentiometer, it can realize the remote and wireless control of the engine throttle within 30m, realize the adjustment of the engine speed, the signal transmission is stable, and the response is fast.

1. To ensure safety, check whether the container side loader trailer is working normally and in accordance with the requirements of goods to be lifted before the operation. Make sure that the sidelifter is not overloaded. Refer to the container side loader trailer working range to make sure that the unbalance loading of front and rear does not exceed 10% of that at the corresponding working range and keep the container a proper distance of 300mm~500mm from chassis if it is possible.

2. Two hydraulic arms, mounted on an attached vehicle, on the trailer of a truck, on a standard 2 or 3 axle truck, or on a railroad car, which allows access to the load, make it possible to load or unload standard containers from a maximum weight. The process is executed by means of a radio control system located in the truck.

3. When the load just leaves the ground, please ensure there is no obstacle in the load traveling direction. Do not make the container center beyond the stabilizer's limits, otherwise, it may result in overturn accident. Be sure to keep all wheels in contact with the ground when extending stabilizers. During operation, do not retract stabilizers.

4. The working range of front lift equipment and rear lift equipment should be mostly the same. When a difference occurs, stop one lift equipment and operate another lift equipment, adjust them to enable the front lift equipment is the same work range as the rear lift equipment, then operate them at the same time again.

5. During lifting, make sure the lifter acts smoothly and steady, if the container swing being lifted because of an abrupt operation, stop the operation container side loader trailer at once, restart the operation after quieting down.

6. When performing inspection and maintenance work, be sure to avoid a collision, and do no-knock the parts fiercely to prevent them from distortion, and keep these parts from dust when working on them, in addition, add and inject grease to prolong 20ft container side loader trailer life.

7. All the moving parts of the machine are driven by hydraulic, when you find abnormal sound during operation, stop operation at once, restart operation after get rid of faults.

Advanced test and detection system

Our professional technical team, with a highly responsible scientific research spirit, conducts rigorous machine performance and industrial performance tests on each Container loading trailer. Set up a series of special tests such as boom weld fatigue test, cylinder durability test, complete machine waterproof and fireproof performance test, operating comfort, etc., to provide a strong quality guarantee for the product.

Advanced manufacturing process

Gas-shielded welding is adopted, and each key weld has passed 100% non-destructive testing, which can withstand strict tests. The parts are processed as a whole with high processing accuracy.

Advanced research and development methods

A complete technical research and development center has been established, and a product design concept based on three-dimensional modeling, parametric and modular, has been formed. After accurate and comprehensive finite element analysis and calculation, it has ensured that the Container loading trailer has a reasonable structure and excellent design.

A good after-sales service

Sany Service adheres to the service concept of creating customer value, centering on customer needs, and providing customers with faster, more reliable and more satisfactory services!

1. The remote control device of the 37t container side loader is equipped with an emergency stop switch. When an emergency occurs, people can quickly press this button to achieve protection measures.

2. When the boom is folded and retracted, it should be stable, accurate, without crawling, chattering, impact and abnormal increase in driving power. The lifting cylinder of the boom is equipped with a balanced valve to ensure that the load stops reliably in the air. The alarm devices of various safety protection boxes of the 40 foot container side loader should be accurate, sensitive and reliable.

3. The outrigger cylinder should be equipped with a two-way hydraulic lock to ensure safe operation and driving.

When the pipeline suddenly bursts, the balance valve acts as a hydraulic lock to keep the heavy objects stationary. When the crane drops heavy objects, it can control the falling speed of the heavy objects to avoid Overspeed.

All operating handles and buttons should be light and flexible, work reliably, and be reasonably arranged, and be easy to operate. It should avoid the interference of various manipulating actions or easily cause misoperation.

Use and maintenance of lifting legs

The Container loading trailer must be parked on a smooth cement road or a solid and flat ground, and it is not allowed to use supporting devices to support the semi-trailer on slopes or soft soil roads. It is not allowed to exceed the lifting height. When the lifting height is not enough, rectangular sleepers can be used to pad the lower end of the legs to a proper height.

When unhooking, lift the Container loading trailer to a proper height. First, use the high gear to quickly ground the support base, and then use the low gear to lift it. After the support base is grounded, turn 4-8 revolutions. Lubrication of inner leg: inner leg equipped with oil storage cylinder, screw rod and nut are self-lubricating and maintenance-free, without oil storage

The screw rod, nut motion pair, bearing of the barrel are filled with grease twice a year or as needed, and the inner leg is repeatedly extended and retracted several times by turning the handle. Lubrication of outer legs: The large and small bevel gears in the left and right outer legs are filled with grease twice a year or as needed. The lubrication of the high-speed gearbox; the gears in the Container loading trailer gearbox are filled with grease twice a year.

1. Lifting crane. The hydraulic 37 ton container side loader trailer and removes the container (from the ground, loading station, another car, railway wagon, or from the top of another container placed on the ground or other location) or out of the chassis. These cranes are placed on top of the container side loader trailer chassis, and they are usually able to travel along the chassis moved by hydraulic cylinders or hydraulic motors to load varying container lengths.

2. Power supply. Generally, cranes are powered by diesel engines or gasoline engines mounted on trailers, and cranes are sometimes powered by the power take-offs of trucks or tractors.

3. The tractor/cab of the towing trailer is powered by the power output shaft (PTO) in some cases. The tractor/cab always provides compressed air for the wheel brakes of the container side loader trailer. Under normal circumstances, if the power forklift is not connected to the tractor, it cannot be operated, because even if the power pack is under the power forklift, the tractor will provide compressed air for the trailer brake and provide extra stability for the lifting operation.

4. The chassis can bear the weight of the container and support the crane during loading. A remote control, a device with joysticks and buttons, is usually connected by multiple pairs of wires or radio signals, allowing operators to walk around the container and observe the device from different angles during operation. The container side loader trailer is designed to lift up to 45 tons, despite the existence of smaller machines.

5. Stabilize the legs. They are equipped with hydraulic feet that can lift loads up to 45 tons container side loader. They can be adjusted to help operate on uneven ground and promote greater safety margins and load restrictions when stacking containers.

6. Chain, during the hoisting process, the chain is fixed from the top of the crane to the corner casting at the bottom of the container. There is a special linking device that when placed between two 20-foot containers, the user can lock the two 20-foot containers together so that container handlers can lift them as if they were 40-foot containers.