Zimbabwe customers has received 3 Axle 45000L fuel tanker trailer

Regardless of whether you have used a semi-trailer before or have not used a semi-trailer, you will have a lot of doubts about the tanker.The following are the problems that many customers often encounter.

3 Axle Fuel Tanker Trailer For Sale

3 Axle Fuel Tanker Trailer For Sale

Fuel tanker, also known as fuel tank trailer, oil tanker trailer or monoblock trailer, are specialised vehicles which transport liquid fuels. These fuel tankers are designed specifically to contain and safely transport fuels like petrol, diesel and even heavy fuel oil (HFO). Many different types of tankers exist as each type caters to the fuel they transport.

Fuel tanker trailer manufacturer-TITAN adopt advanced design concept. TITAN can customized the tankers for you according to your request. To fabric the most durable tankers, especially for Africa Market, considering the road condition. This distortion resistance, earthquake resistance and bump, make your transport safety, also beneficial.

3 Axle Semi Tanker Trailer

3 Axle Semi Tanker Trailer

As a means of transporting dangerous goods, fuel tanker trailer often has many large-scale events. TITAN tanker trailer adopt advanced design concept. We can customized the tankers for you according to your request. To fabric the most durable tankers, especially for Africa Market, considering the road condition. This distortion resistance, earthquake resistance and bump, make your transport safety, also beneficial.

1. The vehicle braking, lighting, and turn signal safety systems meet the operating requirements, the tire specifications are qualified, the wear is normal, and the retreaded tires are not used.

2.The acid tanker trailer number plate is installed intact, the safety inspection signs and insurance signs are placed correctly, the driving license, road transportation license, and road transportation permit for highly toxic chemicals are complete and valid and can be carried with the vehicle.

Details of 45000L Fuel Tanker Trailer

Details of 45000L Fuel Tanker Trailer

3. The emergency cut-off device for the transportation of liquid hazardous chemicals tankers is in good condition and is in a closed state.

4. Safety devices such as vehicle marking lights, signs, reflective signs, side rear protective devices, and fire extinguishers are well configured, and satellite positioning devices are working properly.

1. Choose a reasonable driving route with good traffic conditions, stay away from towns and residential areas, and do not enter the prohibited areas of dangerous goods transport vehicles. Vehicles transporting highly toxic chemicals must be driven according to the time and route approved by the public security organs, and may not be changed at will.

2. Maintain a safe driving speed. In any case, the driving speed should not exceed 80km / h. At night, under low visibility conditions such as rain, fog, snow and snow, you must drive at a reduced speed.

3. Maintain a reasonable driving distance from the vehicle in front, and increase the separation distance in case of rain, fog, snow and other bad weather.

Details of Oil Tanker Trailer

Details of Oil Tanker Trailer

4. It is not allowed to change lanes arbitrarily while driving. Highway traffic must be driven in the specified lanes.Drivers should keep their attention. They should stop and rest every 2 hours or so, and check the technical status of the vehicle in time to ensure that the emergency shut-off valve is closed.

It is strictly forbidden to use non-conductive polyethylene hoses as oil pipelines for oil delivery crane pipes, and it is strictly forbidden to use plastic containers when handling oil products.

Equipment that meets technical specifications and safety requirements must be used. The automatic control, remote control, measuring instruments, valves and other equipment of the oil delivery station must be regularly inspected and calibrated, and related management systems should be formulated, especially the material of the oil delivery equipment cannot be underestimated.

The above are the most basic safety common sense.

To ensure stability: A liquid fluctuates to all directions in the tank when the trailer is running on a slope. If the fuel tanker trailer has a large capacity, the fluctuations will cause major changes in the center of mass.

The efficiency principle: Transporting each liquid in a different tanker is more expensive and inefficient. Trailers with multiple compartments can transport different grades of gasoline in one trip. A service station can receive all the products needed in just one trip.A trailer with different compartment can transport different kinds of liquid at the same time. This reduces the transportation cost and saves fuel because the trips are reduced to one.

This, in turn, will cause major changes of the axle load, which affect the stability of the truck and trailer. The instability may cause the trailer to jackknife or rollover. Using a multi-compartment model reduces the changes of the axle load and hence keeps the trailer stable.

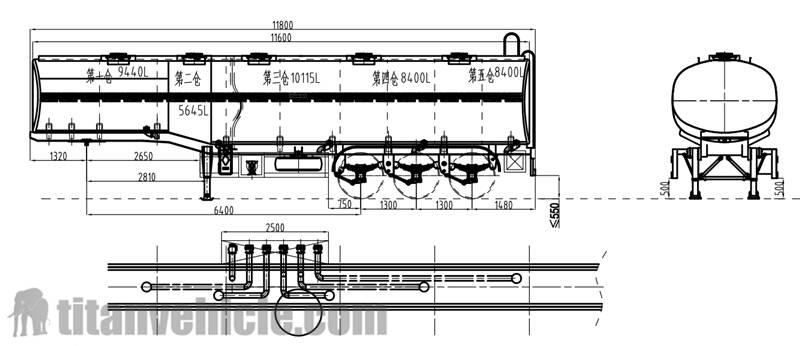

Drawing of Fuel Tanker Trailer

Drawing of Fuel Tanker Trailer

A specific type of hose is used during the process of loading and offloading the fuel. These hoses are designed to fit the opening on the tankers and usually have gaskets and seals in place to reduce and limit the amount of potential spilling. During the loading process, the vapour of the fuel is carefully monitored as these gases are highly flammable. Once loaded, the trucks are secured for travel and can head off to their destination, which is fitted with the same type of hose to properly offload the fuel.

Fuel tankers use highly technical equipment to ensure the process of loading, transporting and offloading the fuel product is as safe and wasteless as possible. Many fuel tankers are fitted with special devices that read the quantity of fuel being loaded, control pressure, and even regulate temperature!