Oil-filled equipment does not comply with specifications, equipment malfunctions, oil spills, electrostatic discharge, and human error.Operation is the main cause of the fuel tanker trailers.In order to ensure the safe use of tank trucks, we should proceed from the following aspects

3 axle Fuel tanker trailer for sale

3 axle Fuel tanker trailer for sale

1.Electrostatic grounding cannot be ignored. From the perspective of fuel tank trailers, the main parts of static electricity are pumps, filters and pipes. The static electricity generation of the tanker filling system is much higher than that of the ground pipeline. Relevant information reflects: If a 250m long and 100mm diameter underground pipe is used to pump oil at a flow rate of 2500L/min, the charge from the fuel gun is generally only, and the charge is exceeded after passing through the fuel tank trailers. Produced by the filter of the tank truck, so if the tank truck is not grounded for loading and unloading operations, the tank body can carry a voltage of more than 10kV; therefore, for hidden dangers of static electricity, the following measures must be taken:

(1) Connect the grounding wire before filling the oil, and often check whether it is in good condition and whether the grounding resistance meets anti-static standards.

(2) The crane tube must reach the bottom of the oil tank when filling the oil, the mouth of the tube should be kept at about 15cm from the bottom of the tank, and the initial filling speed should be strictly controlled within 1m/s until the oil outlet is submerged and then gradually increase the flow rate, but The maximum flow velocity should not exceed 4.5m/s to prevent electrostatic accidents caused by splashing;

(3) After the oil filling is completed, the ground must be disconnected after 5 minutes of oil stabilization. Because after the oil is installed, the oil surface potential will remain for several minutes because the oil flows in the tank.

2.Don't relax your vigilance because of good grounding. Electrostatic grounding can only conduct static electricity on conductors (metal, human body, conductive liquids, etc.) that are closely connected to it, and static charges on isolated conductors and non-conductors (oils, rubber, resin, glass, etc.) that are not connected to it But it is helpless or difficult to remove in a short time; therefore, the operator should strictly follow the operating rules and pay attention to potential hazards that may occur at any time while being electrostatically grounded, and at the same time master the emergency methods and correct handling of various emergencies Rescue measures.

3.Prevent people from being charged. During loading and unloading operations, the human body must be in contact with work objects and objects to produce friction, which is very easy to generate static electricity and may form electrostatic discharge. If it happens to encounter flammable and explosive oil vapor at this time, it will explode. accident. The operator must wear anti-static work clothes and anti-static shoes during the operation, the purpose of which is to ground the human body. In addition, the shoes worn should be thin nylon socks or other conductive socks. It is strictly prohibited to paste insulating film on the antistatic soles, and regular inspections should be made.

4.Equipment that meets technical specifications and safety requirements must be used. The automatic control, remote control, measuring instruments, valves and other equipment of the oil delivery station must be regularly inspected and calibrated, and related management systems should be formulated, especially the material of the oil delivery equipment cannot be underestimated. It is strictly forbidden to use non-conducting polyethylene hoses as oil pipelines for oil delivery crane pipes, and it is strictly forbidden to use plastic containers when handling oil products. The above are the most basic safety common sense. At the same time, the static grounding device cannot be made up, and it is necessary to strictly follow the specifications, install it carefully, and check it regularly. For the current universal use of clamps and magnetic joints for grounding, they should not be randomly clamped or adsorbed on random parts of the tank truck, even on the painted surface. This is extremely detrimental to anti-static, but also a big hidden danger.

5.The accident caused by the conversion of oil should also be paid enough attention. This kind of accident mainly occurs when using a tank truck to install diesel. The flash point of gasoline is lower than diesel. If diesel is injected into a tank car containing gasoline vapor, the gasoline vapor is absorbed by the poured diesel liquid. When the pressure is reduced, the air is drawn into the tank truck, and a flammable mixture is formed somewhere between the liquid surface and the air suction point. An explosion accident will occur when the static electricity accumulates and discharges. Therefore, when it is necessary to change and refuel, the gasoline in the tank truck must be cleaned first, and the operation should be carried out in strict accordance with the operating regulations.

In order to prevent rust, the surface of the oil tanker trailer is coated with anti-rust paint and decorative paint. A container indicator is installed in the middle of the side of the oil tank. When adding oil to the tank or transferring oil to the outside, the volume in the tank can be directly indicated. (Optional )

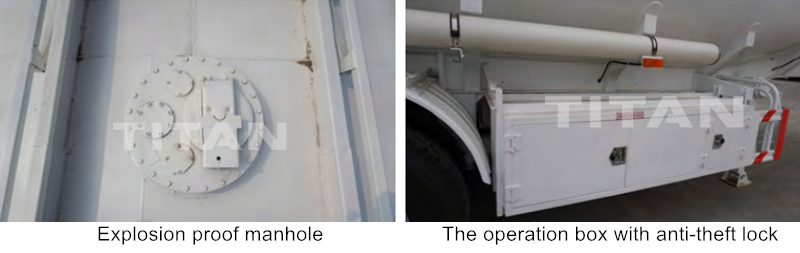

The mouth of the tank is 500mm in diameter for maintenance. The large cover is fastened to the tank mouth plate by bolts, and the small cover and the large cover are connected together by a supporting pin and an ear plate. Turning the small cover on the handle clockwise can make the small cover compact. Reverse, after removing the ear plate, the small cover can be opened, and a breathing valve is installed on the upper side of the large cover.

1. Purpose of oil tanker oil pipe recovery system:

During the loading and unloading of tank trucks, fully enclosed gas recovery is achieved to limit the discharge of oil and gas to the atmosphere. While the tank truck unloads the oil through the unloading pipeline, the oil and gas in the oil tank of the gas station returns to the tank truck through the return air pipeline. The semi tanker trailer brings the oil and gas back to the oil depot for processing, so as to achieve the purpose of oil and gas recovery.

2. Use of subsea valve:

The subsea valve series, also known as the emergency cut-off valve, is installed at the bottom of the tank body, and can replace the traditional top-loading refueling for bottom-loading refueling. A cut-off groove is designed on the valve body. When an accident occurs in the tank truck, the cut-off groove is disconnected, and the vehicle bottom pipeline and the tank body are cut off without affecting the seal of the tank body, which effectively prevents the oil in the tank from leaking, thereby ensuring oil Tank safety.

3. Use of breathing valve:

When the breathing valve is dumped 70o, the sealing ball in the valve is dumped to form an effective seal to prevent the oil from leaking out. Oil-drilling hole use: installed at the preparation port on the manhole cover, dipstick or liquid level gauge can be added.

4. Use of safety valve:

Specially designed for oil tanks, chemical tanks and other tank products, set different opening pressures according to user needs to meet different needs. The main body is made of stainless steel, which is corrosion-resistant and highly closed, suitable for various environments.

5. Anti-overflow sensor:

Uses: The anti-overflow electronic sensor is widely used in various types of containers and tanks. When the liquid is sealed and filled, it is a safety device that alarms in advance to prevent the liquid from overflowing and leaking. It is installed on the manhole cover on the top of the container tank. When the bit reaches the warning limit, the sensor will automatically alarm and break.