Dry bulk tanker trailer is also called cement bulker, silobas or silo trailer. It is mainly used for the bulk packing of powder dry materials such as fly ash, cement, lime powder, ore powder, granular alkali, aluminum powder, etc. transport. We often see such vehicle situations at cement plants, cement warehouses, and large construction sites.How to use the powder tank truck? Below we will share with you.

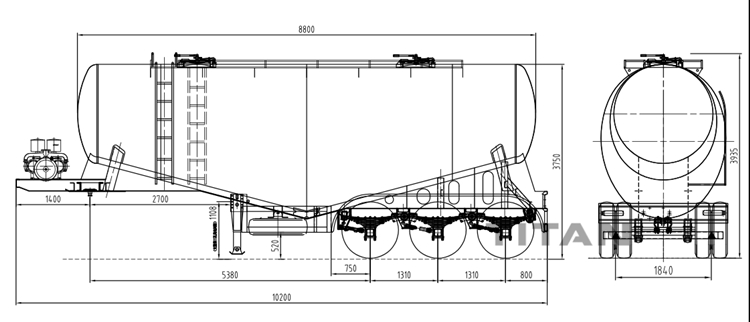

3 Axle cement tanker trailer

3 Axle cement tanker trailer

1. Perform routine inspection according to the axle axle manual of the dry bulk tanker trailer;

2. Check the tank, frame, suspension and key components for cracks or loose bolts;

3. Check whether the lighting and braking system are normal;

4. Check whether the manhole, intake valve and discharge valve can be opened and closed normally;

1. Before opening the feeding cover, you must open the pressure relief valve and the inlet pipe ball valve to remove the remaining air in the tank before opening the tank cover to avoid injury.

2. You should always pay attention to whether the pressure gauge is working properly, to prevent the pressure gauge from malfunctioning and overpressure, and the tank bursting.

3. Always check the safety valve to ensure that the pressure is released at 0.2Mpa, and the pressure inside the tank must not exceed 0.2Mpa.

4. Often check whether the operation table is working properly, so as not to overrun and damage the air compressor.

5. Always listen to the sound of power take-off and air compressor rotation. If there are abnormal sounds, stop troubleshooting immediately.

1. Before unloading, check whether the unloading disc valve, external air source interface, exhaust valve, and two feeding ports are closed and tightened. If they are not tightened, tighten them first to prevent air leakage.

2. Start the engine and shift the transmission to neutral while pressing the clutch pedal to completely separate the transmission from the engine.

3. Turn on the power take-off solenoid valve switch, and slowly release the clutch pedal to rotate the air compressor.

4. Adjust the control handle of the control mechanism to adjust the speed of the air compressor to about 900r / min and stabilize it.

5. When the pressure reaches 0.18MPa, first open the auxiliary blowpipe, then open the front and rear bin discharge disc valves to start discharging, after which the pointer of the air compressor will stabilize to a certain value.

6. When the air pressure drops to 0.04Mpa, the back bin has been unloaded. Close the blower tube, open and close the back bin valve several times, and then close the back bin valve and the back bin intake valve. , After which the pressure will rise and stabilize to a certain value.

7. When the pressure of the barometer reaches 0MPa, the discharge is completed, the air compressor is closed, and the discharge disc valve is closed.

Bulk cement truck for sale

Bulk cement truck for sale

1. During maintenance (or entrust a repair station, repair shop, etc. for maintenance), it must be carried out according to the instructions, otherwise quality problems or accidents caused by improper maintenance.

2. Inject the grease-lubricated parts of the whole vehicle once before the operation of the new silo semi trailer, at least twice in the first month.

3. After each disassembly and assembly of the traction pin and wheel, the tightening of the traction pin bolt and the vehicle nut must be checked to ensure that the specified torque is reached.

4. Air compressors must be replaced with oil (general diesel engine oil) after half a month of use or 15 hours of cumulative work, and the oil should be replaced every three months or 120 hours of use; the air filter must be cleaned once 24 hours of cumulative work. The filter element needs to be replaced after working for 120 hours.

5. Regularly keep the inside and outside of the tank clean, and clean up the ash deposits on the top of the tank in time to prevent corrosion of the tank. If corrosion is found, maintain it in time.

6. It is forbidden for the air compressor to work over time. Generally, the rated working time of the single cylinder air compressor is 1 hour, and the rated working time of the double cylinder air compressor is 2 hours. If the discharge cannot be completed within this rated working time, please temporarily stop and cool for 20 minutes before starting the air compressor.

After the first load or two weeks after the first drive, the tightening of all bolts and nuts connected to the tire bolts, suspension system, and main and auxiliary frames must be checked to ensure that the specified torque is reached.

1. It is forbidden to use the air compressor at a low or high speed during normal unloading. The air compressor speed is controlled at 900 ~ 950 rpm (or the rated speed according to the air compressor instruction manual).

2. The rated working pressure is 0.2MPa, and the user’s maximum working pressure is not allowed to exceed 0.22MPa; if an external air source is used, the maximum pressure range is 0.2 ~ 0.25MPa, if it is greater than 0.25MPa, a pressure reducing valve needs to be installed on the external air source pipeline .

3. When there is residual pressure in the tank, it is strictly forbidden to open the feed inlet (manhole cover).

4. If the working pressure, conveying distance and conveying materials are beyond the above range, it should be clearly stated before signing the contract and indicated in the contract. Our company will give targeted suggestions and product design.

5. Please clean the dust accumulation inside and outside the manhole cover frequently, especially the dust accumulation on the flange surface and the inner chute, otherwise it will easily leak air and the switch will not be flexible.

Customer feedback of cement tanker trailer

Customer feedback of cement tanker trailer

1. When the inflation pressure is established, when the pressure in the tank is too high and the safety valve is opened, the exhaust valve can be opened to reduce the pressure.

2. When water enters the tank, the water should be discharged in time through the two drain valves at the bottom of the tank. If the fluidized bed canvas gets wet, the fluidized bed canvas should be replaced in time to avoid agglomeration of the cement.

3. During the discharging process, if other abnormal situations need to be terminated, you can close the discharging valve first, and then open the exhaust valve.

Welcome to click “Blog“, you can get more article about our trailers.