What is a Fuel Tanker Trailer?

Fuel tanker, also known as fuel tank trailer, oil tanker trailer or monoblock trailer, are specialised vehicles which transport liquid fuels. These fuel tankers are designed specifically to contain and safely transport fuels like petrol, diesel and even heavy fuel oil (HFO). Many different types of tankers exist as each type caters to the fuel they transport.

Fuel tanker trailer manufacturer-TITAN adopt advanced design concept. TITAN can customized the tankers for you according to your request. To fabric the most durable tankers, especially for Africa Market, considering the road condition. This distortion resistance, earthquake resistance and bump, make your transport safety, also beneficial.

3 Axle fuel tanker trailer

3 Axle fuel tanker trailer

Why do fuel tankers have several compartments?

The efficiency principle: A trailer with different compartment can transport different kinds of liquid at the same time. This reduces the transportation cost and saves fuel because the trips are reduced to one.

Transporting each liquid in a different tanker is more expensive and inefficient. Trailers with multiple compartments can transport different grades of gasoline in one trip. A service station can receive all the products needed in just one trip.

To ensure stability: A liquid fluctuates to all directions in the tank when the trailer is running on a slope. If the fuel tanker trailer has a large capacity, the fluctuations will cause major changes in the center of mass.

This, in turn, will cause major changes of the axle load, which affect the stability of the truck and trailer. The instability may cause the trailer to jackknife or rollover. Using a multi-compartment model reduces the changes of the axle load and hence keeps the trailer stable.

Gas tanker trailer for sale

Gas tanker trailer for sale

How does a fuel tanker work?

Fuel tankers use highly technical equipment to ensure the process of loading, transporting and offloading the fuel product is as safe and wasteless as possible. Many fuel tankers are fitted with special devices that read the quantity of fuel being loaded, control pressure, and even regulate temperature!

A specific type of hose is used during the process of loading and offloading the fuel. These hoses are designed to fit the opening on the tankers and usually have gaskets and seals in place to reduce and limit the amount of potential spilling. During the loading process, the vapour of the fuel is carefully monitored as these gases are highly flammable. Once loaded, the trucks are secured for travel and can head off to their destination, which is fitted with the same type of hose to properly offload the fuel.

Chemical tanker trailer and Fuel Tank Full Trailer

Chemical tanker trailer and Fuel Tank Full Trailer

As a means of transporting dangerous goods, diesel fuel tanker trailer often has many large-scale events. Therefore, safety measures must be put in place in daily life. Perhaps a small action can avoid the above disasters. Today, we will popularize the knowledge of accident prevention of truck fuel tanker:

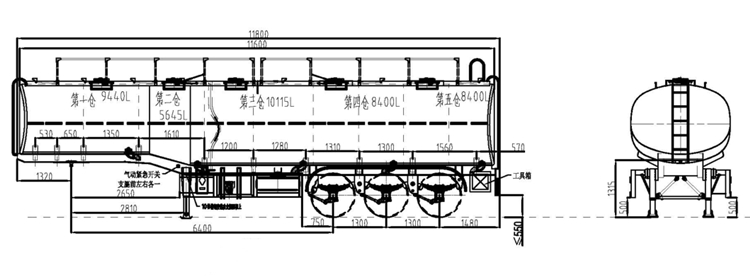

Draw of fuel tanker trailer

Draw of fuel tanker trailer

Diesel fuel tanker trailer should have the following basic conditions:

(1) The tank body must be provided with an electrostatic grounding terminal, and an obvious mark is painted on the terminal; install a conductive rubber towing zone, and keep it on the ground after filling with oil.

(2) Equipped with two dry powder fire extinguishers over 4 kg, the location should be reasonable and easy to use.

(3) The actual loading capacity shall not be greater than the approved loading capacity

(4) Install an effective fire cap on the exhaust pipe, and the circuit system should have a device for cutting off the main power supply.

(5) The relevant certificates such as the vehicle driving license and the hazardous chemicals permit are complete.

(6) The tank body and accessories are good and effective, with no damage or deformation affecting the strength, no serious corrosion, and no leakage. The diesel fuel trailer is qualified by the qualified inspection department..

Details of fuel semi trailer

Details of fuel semi trailer

Therefore, for the hidden danger of static electricity, the following measures must be taken:

1.Connect the ground wire before filling the oil, and often check its intact condition. We also need to pay attention to whether the grounding resistance meets the anti-static standard.

2.The crane pipe must reach the bottom of the petrol tanker trailer when filling oil, the pipe mouth should be kept at about 15cm from the bottom of the tank, and the initial filling speed should be strictly controlled within 1m/s, until the oil outlet is submerged, then gradually increase the flow rate, but The maximum flow velocity should not exceed 4.5m / s to prevent electrostatic accidents caused by spraying;

3.After the oil filling is completed, the ground must be disconnected after 5 minutes of oil stabilization. Because after the oil is installed, the oil surface potential will remain for several minutes because the oil flows in the tank.

Strictly abide by the operating regulations

Don't relax your vigilance because of good grounding. Electrostatic grounding can only conduct static electricity on "conductors" (metals, human bodies, conductive liquids, etc.) that are closely connected to it. Static charge is helpless or difficult to remove in a short time;

Therefore, while electrostatically grounding, the operator should strictly follow the operating procedures and pay attention to the hidden dangers that may arise at any time, and at the same time master the emergency methods and rescue measures for correctly handling various emergencies.

Therefore, while electrostatically grounding, the operator should strictly follow the operating procedures and pay attention to the hidden dangers that may arise at any time, and at the same time master the emergency methods and rescue measures for correctly handling various emergencies.

Regular inspection of safety equipment

Equipment that meets technical specifications and safety requirements must be used. The automatic control, remote control, measuring instruments, valves and other equipment of the oil delivery station must be regularly inspected and calibrated, and related management systems should be formulated, especially the material of the oil delivery equipment cannot be underestimated. It is strictly forbidden to use non-conductive polyethylene hoses as oil pipelines for oil delivery crane pipes, and it is strictly forbidden to use plastic containers when handling oil products. The above are the most basic safety common sense

At the same time, the static grounding device can not be made up, and it is necessary to strictly follow the specifications, install it carefully, and check it regularly. For the current commonly used clamps and magnetic joints to be grounded, they should not be randomly clamped or adsorbed on any part of the diesel tanker trailer for sale, even on the painted surface. This is extremely detrimental to anti-static, but also a big hidden danger.