Tanzanian customer's 4 Axle tipper trailer has been shipped.

Customer contacted us again and wanted to buy 4 axle tipper trailer, which mainly transports sand. The dump truck trailer was disassembled and packed in containers to save space and freight. Now it has been sent to Tanzania.

With the rapid economic development, the dump truck industry is developing towards medium and large tonnage, especially in recent years.

Over the years, Tipper Semi Trailer's own advantages have gradually increased its sales. Among them, Tipper Semi Trailer is divided into two unloading methods: Side tipper trailer and dump tipper trailer.

Tipper Semi Trailer For Sale

Tipper Semi Trailer For Sale

As Tipper Semi Trailer tipped over accidents during unloading,In order to avoid similar accidents, we now discuss the causes of dump tipper trailer rollover during unloading, so that the manufacturer can indicate to the user in the instruction manual to avoid similar accidents and cause unnecessary losses.

The end dump trailer is mainly composed of a tractor and a semi-trailer. The main vehicle and the semi-trailer are connected by a saddle, usually a front compound cylinder

When the Tipper Semi Trailer dumps sideways when unloading, it usually occurs when the semi-trailer is unloading, and the vehicle is parked on an unsteady or uneven road surface. As the rear inclination angle of the carriage increases, the cargo content is continuously improved.

Production of Dump semi trailer

Production of Dump semi trailer

1. User overloaded work;

2. The left and right sides of the load are uneven, especially the load center of mass is biased to the lower side of the tire;

3. The locking mechanism of the rear door of the carriage failed to open;

4. Deformation of tires and leaf springs;

5. Equipped with sand material with larger water content.

According to the above analysis, the control elements of end dump during unloading should be as follows:

1. The used and manufacturer's after-sales service personnel cannot arbitrarily adjust the overflow of the overflow valve of the hydraulic system.Pressure to avoid the occurrence of overload;

2. The vehicle should be parked on a solid and flat road to avoid a height difference between the left and right tires. For this-point system.The manufacturer should indicate in the instruction manual;

4. The manufacturer should explain the materials contained in the rear-tilting dump truck, especially in winter.The transportation of wet sand and other materials must be clearly stated;

Package of 4 Axle End Dump Trailer

Package of 4 Axle End Dump Trailer

1. The unloading site must be actually inspected to understand the actual situation.

2. For vehicles equipped with rear box plate locking mechanism, pay special attention to the release before unloading.

3. Don't panic when you feel that a side tipping phenomenon occurs, let alone switch the control valve to

The lowering position of the carriage, because the carriage falls back down by its own weight, this operation will produce greater danger.

1. Double-plate main beam for heavy-duty dump trailer, which have stronger carrying capacity, it is not easy to damage.with 4 units vice beam and cross balance beam. The lattice structure of the side door makes the side door more solid.

2. Hydraulic cylinder: The heavy-duty cylinder with a wider diameter, stronger lifting capacity and higher height, which makes the lifting more stable and does not easy to roll over.

3. Flip Bracket: 4 units flip brackets, which can make the rear end more evenly loaded during unloading, and it is not easy to damage the trailer.

4. Strengthened Ribs, unique structure design to maximize the payload.The leaf spring is widened and thickened, the shock absorption effect is good.

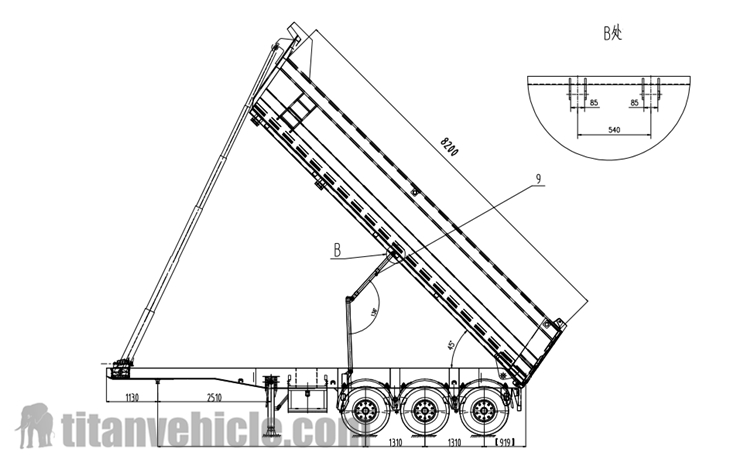

Drawing of Tipper Semi Trailer

Drawing of Tipper Semi Trailer