Bulk cement tanker trailer is a kind of mechanical product that mixes and disperses some powdery objects and is often used in the construction industry. This machine uses a stainless steel stable material, and will not cause rust due to long-term contact with moisture. The compact structure is also more flexible during use. The operation is simple, but some abnormal sounds during the work make most people suffer from headaches. Especially the part of the oil extraction machine has obvious knocking sound. So what is the cause, let's analyze it in detail below.

3 Axle bulk cement tanker trailer for sale

3 Axle bulk cement tanker trailer for sale

Generally speaking, when the concrete pump truck oil changer changes the load, the middle and lower parts of the cylinder can have obvious empty sound, and it will change rapidly with the increase of load or speed, which causes this situation. It is because the excessive wear of the connecting rod pads causes the gaps generated by the surrounding equipment to be relatively large.

When the female end of the cement bulker is connected to the child end, the air compressor starts to blow compressed air into the tank. When the required pressure gauge shows 0.2Kpa, it will start to discharge ash, which will take a long time. Shaking around a fixed value, then working normally, when there is not much cement left in the 3 axle bulk cement tank trailer, the relative space in the tank has increased,

The pointer reading starts to drop, and soot blowing continues. When the pointer suddenly drops to the lowest point (close to the value of "0" on the pressure gauge), at this time, the bulk cement flow tank air outlet quickly sprays a large gas-ash mixed air flow. This indicates that the ashing process of the mobile tank is over.

Package of cement trailer

Package of cement trailer

After this process is completed, if the cement bulker driver wants to check the residual material in the 50Cbm bulk cement trailer, it is preferred to turn on the unloading switch to exhaust the residual gas in the tank, so as to avoid the accident of rushing the tank cover when opening the tank cover. You can check the air pressure in the tank through the barometer, 0 means no air pressure in the tank.

Accept the process of bulk cement and precautions: the user must master the process of unloading ash in bulk cement, otherwise whether the ash material in the bulk cement tanker will be unloaded will affect the benefit of the enterprise, therefore, it is necessary to master the process Changes and various characteristics of pressure gauges.

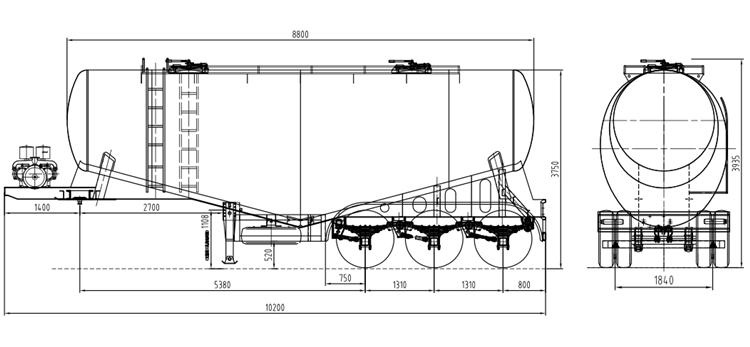

Drawing of dry bulk trailer price for sale

Drawing of dry bulk trailer price for sale

1.The exterior of the tank is beautiful and practical

After the design of the tank is completed, the following is the actual manufacturing work. TITAN adopts laser cutting, which can improve the precision to 0.01mm. The mirror cut is formed at one time, which can reduce the hot melt area of the cutting as much as possible, so that the steel plate elements are unchanged, the rigidity will not be lost and the stress concentration will not occur.

Then, it is controlled by an automatic numerical control plate rolling machine, the cylinder body is formed at one time, the inside of the plate will not be damaged, and the forming quality is stable and reliable.

Next is the welding work. A good welding process can not only keep the weld of the tank beautiful, but also ensure that there is no concentrated stress at the weld of the steel plate, and maintain the strength of the steel plate of the tank.

The tank body of 3 axle cement tanker adopts an automatic welding process and is welded on one side and formed on both sides, so that the tank body has better strength.

2.The interior design of the tank should be professional

Next, let's look at the design structure of the fluidized bed inside the tank.

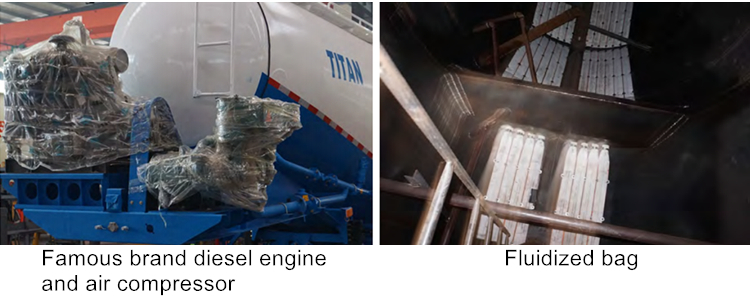

Details parts of 4 axle bulk cement trailer

Details parts of 4 axle bulk cement trailer

The inclination angle of the barrel and side slide of 3 axle cement tanker is greater than 2-3 degrees compared with other tanks in the same industry. This can improve the fluidity of the materials, reduce the residual amount of materials inside the tank and unload the materials as soon as possible. It can reach 1.5 tons per minute.

The discharge port of the cement tank body also adopts an enlarged design, which can ensure that the material can be supplied adequately when discharging, and the material can be discharged at the fastest speed. Moreover, the reinforced support of the discharge pipe, using the triangular stability principle, can ensure that During the unloading process, the pipeline has no displacement and has the best stability.

3.Painting process and environmental protection are very important

After the external shape and internal structure are designed, the tank body needs to be painted. The tank body of 4 axle cement tanker adopts spray + powder spraying process design, which can make the coating life 5-8 years without fading.

And the weather resistance and corrosion resistance of the paint used can be doubled compared with ordinary paint. The thickness of the coating reaches H level, which is less likely to be scratched. Finally, the preliminary treatment does not contain phosphorus and heavy metal materials, which is more environmentally friendly.

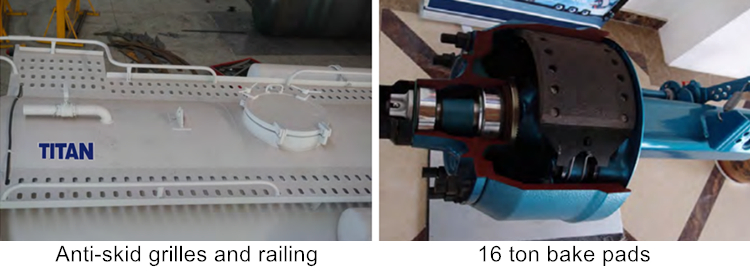

Details of bulk tanker trailer

Details of bulk tanker trailer

4.Vehicle piping design needs to pay attention to details

Finally, the layout and assembly of the external piping of the tank. In terms of pipelines, particular attention must be paid to details. The ball head is made of stainless steel, which is both beautiful and easy to use. The reinforced outer bracket can make the tank bear better strength. Laser welding seam, no stress concentration, make the life of the 3 axle cement tanker longer.

5.New cars can only be shipped if they meet the inspection standards

After the production of the new dry bulk trailer is completed, only after passing the inspection of strict standards can we count as a qualified product.

Titans have test towers, complex road conditions, and vehicle test center test sites. They can accurately test the optimal positioning size of the discharge speed and residue of the tank, the stability of the vehicle during driving, and the braking and safety of the vehicle. Performance, only after the performance of the vehicle has reached the national standard, can it enter the market for customers to use.